Section 2

VINYL & PARQUETRY

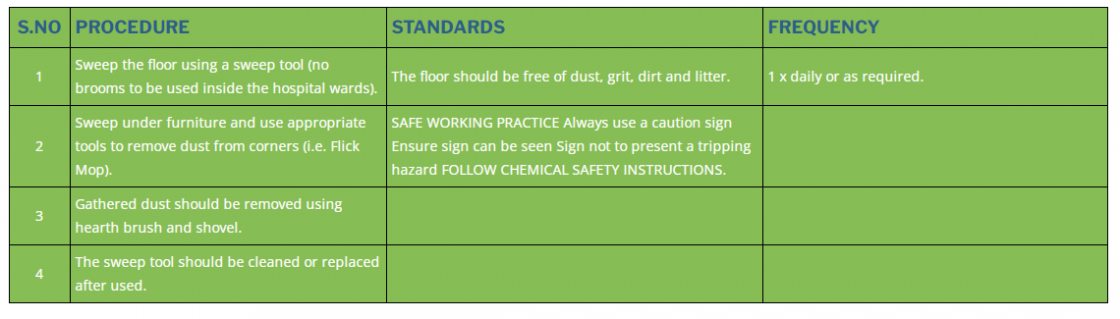

2.1 Vinyl Floor-Sweeping

S.No | Procedure | Standards | Frequency |

1 | Sweep the floor using a sweep tool (no brooms to be used inside the hospital wards). | The floor should be free of dust, grit, dirt and litter. | 1 x daily or as required. |

2 | Sweep under furniture and use appropriate tools to remove dust from corners (i.e. Flick Mop). | SAFE WORKING PRACTICE Always use a caution sign Ensure sign can be seen Sign not to present a tripping hazard FOLLOW CHEMICAL SAFETY INSTRUCTIONS. | |

3 | Gathered dust should be removed using hearth brush and shovel. | ||

4 | The sweep tool should be cleaned or replaced after used. |

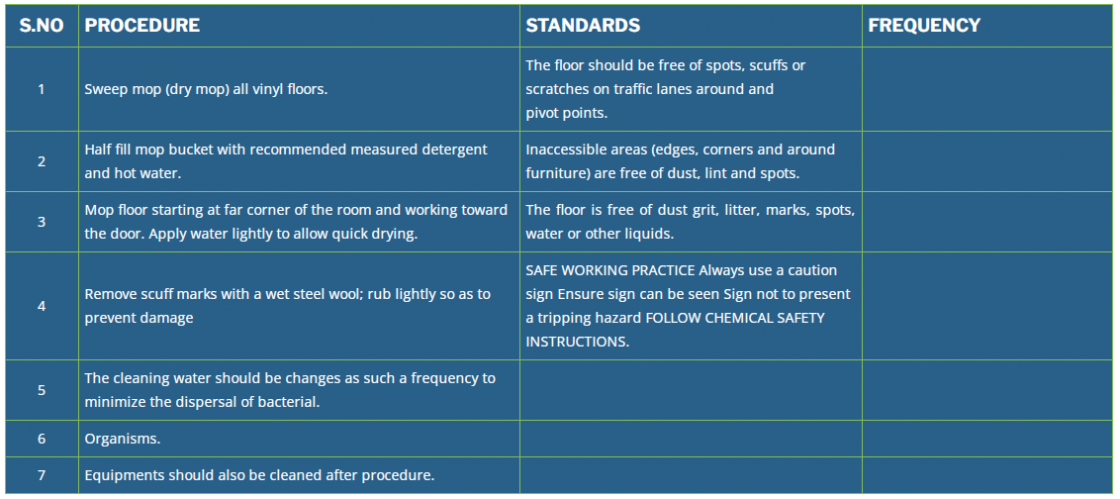

2.2 Vinyl Floors-Wet Mopping (Low and High Maintenance Type)

S.NO | Procedure | Standards | Frequency |

1 | Sweep mop (dry mop) all vinyl floors. | The floor should be free of spots, scuffs or scratches on traffic lanes around and pivot points. | |

2 | Half fill mop bucket with recommended measured detergent and hot water. | Inaccessible areas (edges, corners and around furniture) are free of dust, lint and spots. | |

3 | Mop floor starting at far corner of the room and working toward the door. Apply water lightly to allow quick drying. | The floor is free of dust grit, litter, marks, spots, water or other liquids. | |

4 | Remove scuff marks with a wet steel wool; rub lightly so as to prevent damage | SAFE WORKING PRACTICE Always use a caution sign Ensure sign can be seen Sign not to present a tripping hazard FOLLOW CHEMICAL SAFETY INSTRUCTIONS. | |

5 | The cleaning water should be changes as such a frequency to minimize the dispersal of bacterial. | ||

6 | Organisms. | ||

7 | Equipments should also be cleaned after procedure. |

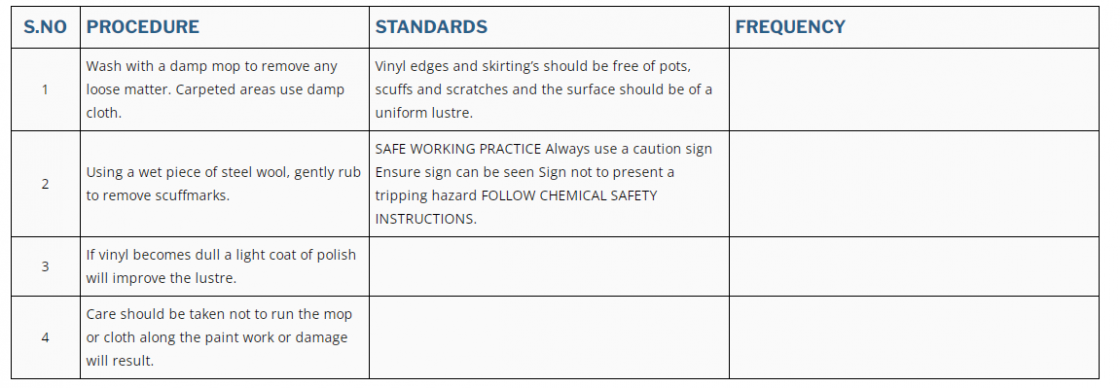

2.3 Vinyl Edgings/Skirting

S.NO | Procedure | Standards | Frequency |

1 | Wash with a damp mop to remove any loose matter. Carpeted areas use damp cloth. | Vinyl edges and skirting’s should be free of pots, scuffs and scratches and the surface should be of a uniform lustre. | |

2 | Using a wet piece of steel wool, gently rub to remove scuffmarks. | SAFE WORKING PRACTICE Always use a caution sign Ensure sign can be seen Sign not to present a tripping hazard FOLLOW CHEMICAL SAFETY INSTRUCTIONS. | |

3 | If vinyl becomes dull a light coat of polish will improve the lustre. | ||

4 | Care should be taken not to run the mop or cloth along the paint work or damage will result. |

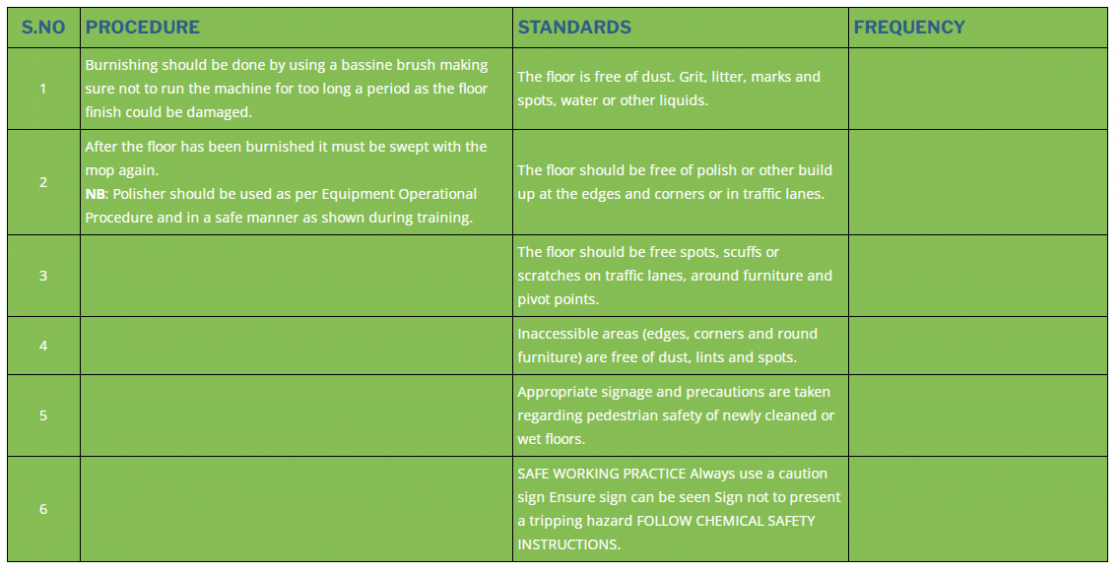

2.4 Vinyl Floors-Burnishing (High Maintenance)

S.NO | Procedure | Standards | Frequency |

1 | Burnishing should be done by using a bassine brush making sure not to run the machine for too long a period as the floor finish could be damaged. | The floor is free of dust. Grit, litter, marks and spots, water or other liquids. | |

2 | After the floor has been burnished it must be swept with the mop again. NB: Polisher should be used as per Equipment Operational Procedure and in a safe manner as shown during training. | The floor should be free of polish or other build up at the edges and corners or in traffic lanes. | |

3 | The floor should be free spots, scuffs or scratches on traffic lanes, around furniture and pivot points. | ||

4 | Inaccessible areas (edges, corners and round furniture) are free of dust, lints and spots. | ||

5 | Appropriate signage and precautions are taken regarding pedestrian safety of newly cleaned or wet floors. | ||

6 | SAFE WORKING PRACTICE Always use a caution sign Ensure sign can be seen Sign not to present a tripping hazard FOLLOW CHEMICAL SAFETY INSTRUCTIONS. |

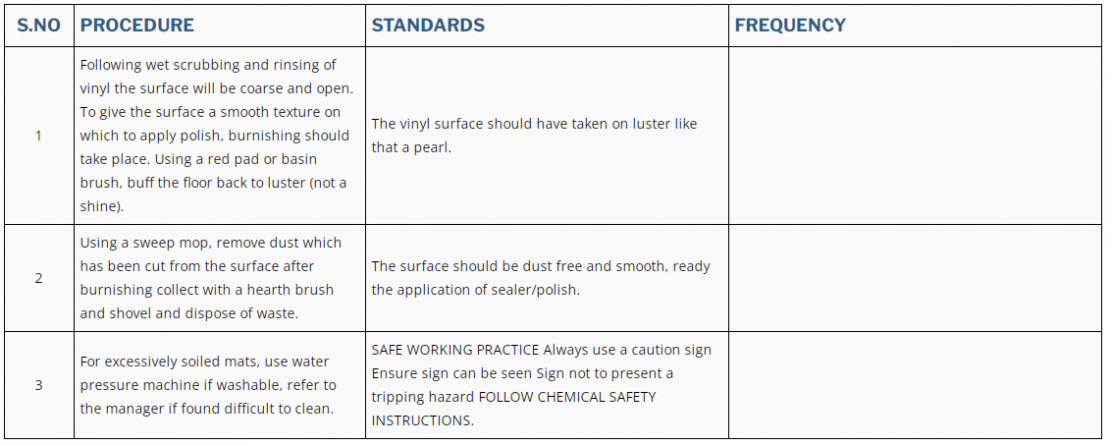

2.5 Vinyl Floors-Wet Scrubbing

S.NO | Procedure | Standards | Frequency |

1 | Following wet scrubbing and rinsing of vinyl the surface will be coarse and open. To give the surface a smooth texture on which to apply polish, burnishing should take place. Using a red pad or basin brush, buff the floor back to luster (not a shine). | The vinyl surface should have taken on luster like that a pearl. | |

2 | Using a sweep mop, remove dust which has been cut from the surface after burnishing collect with a hearth brush and shovel and dispose of waste. | The surface should be dust free and smooth, ready the application of sealer/polish. | |

3 | For excessively soiled mats, use water pressure machine if washable, refer to the manager if found difficult to clean. | SAFE WORKING PRACTICE Always use a caution sign Ensure sign can be seen Sign not to present a tripping hazard FOLLOW CHEMICAL SAFETY INSTRUCTIONS. |

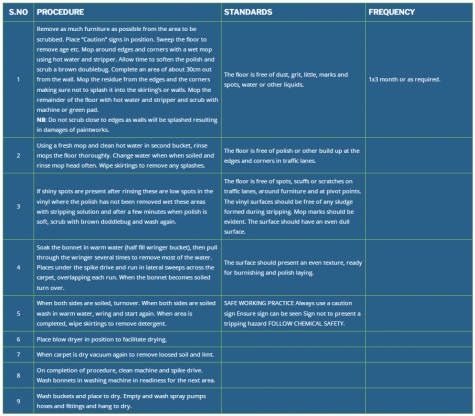

2.6 Vinyl Floors-Burnishing Scrubbed Floor/Following Wet Scrubbing

S.NO | Procedure | Standards | Frequency |

1 | Remove as much furniture as possible from the area to be scrubbed. Place “Caution” signs in position. Sweep the floor to remove age etc. Mop around edges and corners with a wet mop using hot water and stripper. Allow time to soften the polish and scrub a brown doublebug. Complete an area of about 30cm out from the wall. Mop the residue from the edges and the corners making sure not to splash it into the skirting’s or walls. Mop the remainder of the floor with hot water and stripper and scrub with machine or green pad. NB: Do not scrub close to edges as walls will be splashed resulting in damages of paintworks. | The floor is free of dust, grit, little, marks and spots, water or other liquids. | 1x3 month or as required. |

2 | Using a fresh mop and clean hot water in second bucket, rinse mops the floor thoroughly. Change water when when soiled and rinse mop head often. Wipe skirtings to remove any splashes. | The floor is free of polish or other build up at the edges and corners in traffic lanes. | |

3 | If shiny spots are present after rinsing these are low spots in the vinyl where the polish has not been removed wet these areas with stripping solution and after a few minutes when polish is soft, scrub with brown doddlebug and wash again. | The floor is free of spots, scuffs or scratches on traffic lanes, around furniture and at pivot points. The vinyl surfaces should be free of any sludge formed during stripping. Mop marks should be evident. The surface should have an even dull surface. | |

4 | Soak the bonnet in warm water (half fill wringer bucket), then pull through the wringer several times to remove most of the water. Places under the spike drive and run in lateral sweeps across the carpet, overlapping each run. When the bonnet becomes soiled turn over. | The surface should present an even texture, ready for burnishing and polish laying. | |

5 | When both sides are soiled, turnover. When both sides are soiled wash in warm water, wring and start again. When area is completed, wipe skirtings to remove detergent. | SAFE WORKING PRACTICE Always use a caution sign Ensure sign can be seen Sign not to present a tripping hazard FOLLOW CHEMICAL SAFETY. | |

6 | Place blow dryer in position to facilitate drying. | ||

7 | When carpet is dry vacuum again to remove loosed soil and limt. | ||

8 | On completion of procedure, clean machine and spike drive. Wash bonnets in washing machine in readiness for the next area. | ||

9 | Wash buckets and place to dry. Empty and wash spray pumps hoses and fittings and hang to dry. |

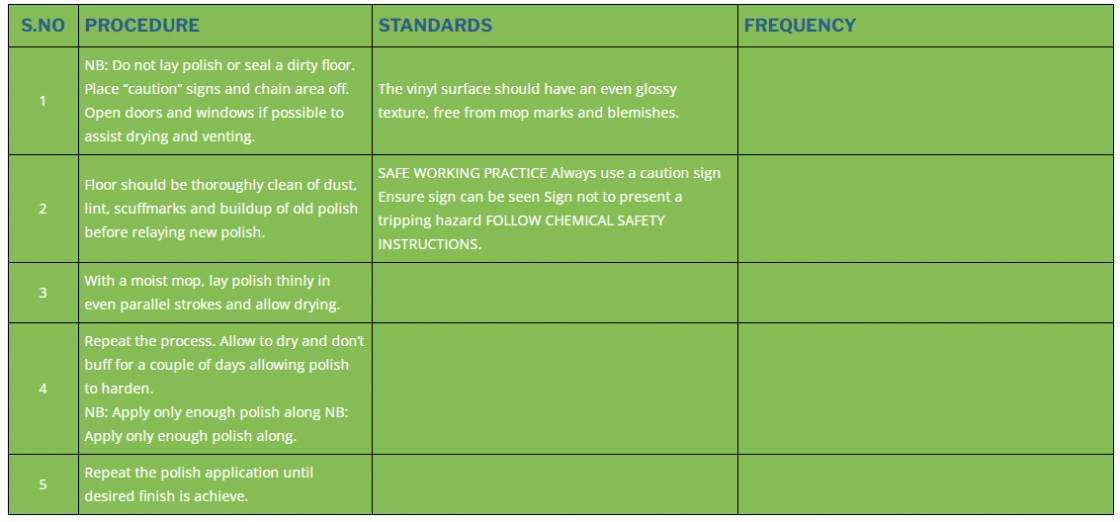

2.7 Vinyl Floors-Laying Polish (High Maintenance Vinyl and Rubber Floors)

S.NO | Procedure | Standards | Frequency |

1 | NB: Do not lay polish or seal a dirty floor. Place “caution” signs and chain area off. Open doors and windows if possible to assist drying and venting. | The vinyl surface should have an even glossy texture, free from mop marks and blemishes. | |

2 | Floor should be thoroughly clean of dust, lint, scuffmarks and buildup of old polish before relaying new polish. | SAFE WORKING PRACTICE Always use a caution sign Ensure sign can be seen Sign not to present a tripping hazard FOLLOW CHEMICAL SAFETY INSTRUCTIONS. | |

3 | With a moist mop, lay polish thinly in even parallel strokes and allow drying. | ||

4 | Repeat the process. Allow to dry and don’t buff for a couple of days allowing polish to harden. NB: Apply only enough polish along NB: Apply only enough polish along. | ||

5 | Repeat the polish application until desired finish is achieve. |

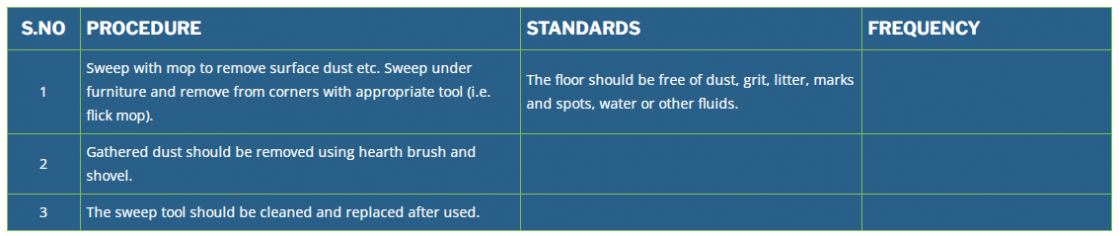

2.8 Parquetry Floors-Sweeping

S.NO | Procedure | Standards | Frequency |

1 | Sweep with mop to remove surface dust etc. Sweep under furniture and remove from corners with appropriate tool (i.e. flick mop). | The floor should be free of dust, grit, litter, marks and spots, water or other fluids. | |

2 | Gathered dust should be removed using hearth brush and shovel. | ||

3 | The sweep tool should be cleaned and replaced after used. |

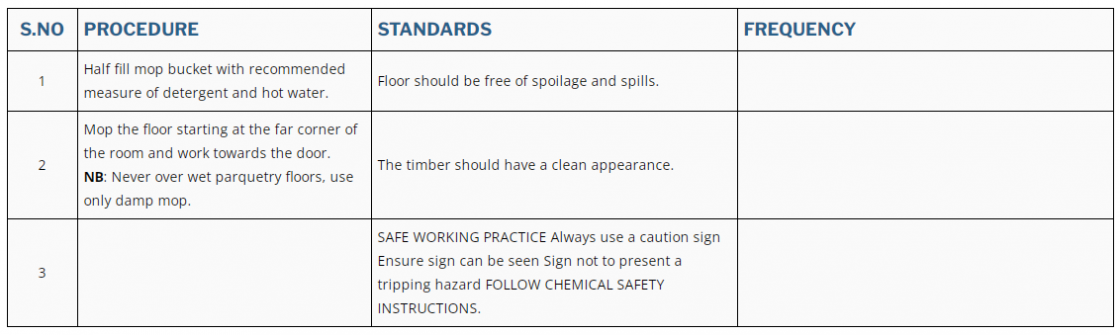

2.9 Parquetry Floor-Wet Mopping

S.NO | Procedure | Standards | Frequency |

1 | Half fill mop bucket with recommended measure of detergent and hot water. | Floor should be free of spoilage and spills. | |

2 | Mop the floor starting at the far corner of the room and work towards the door. NB: Never over wet parquetry floors, use only damp mop. | The timber should have a clean appearance. | |

3 | SAFE WORKING PRACTICE Always use a caution sign Ensure sign can be seen Sign not to present a tripping hazard FOLLOW CHEMICAL SAFETY INSTRUCTIONS. |

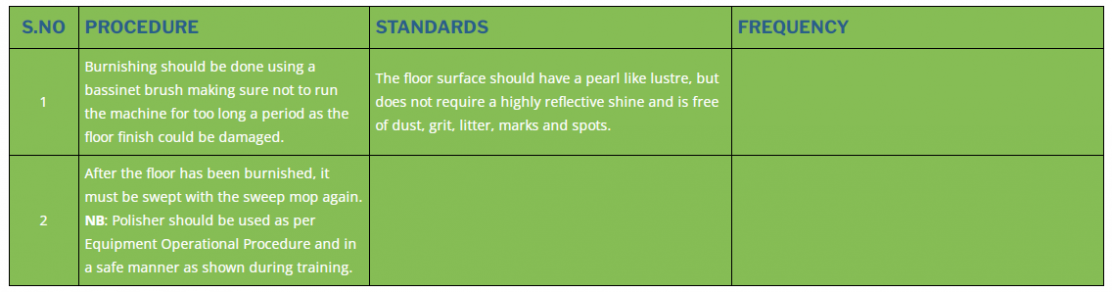

2.10 Parquetry Floors-Burnishing

S.NO | Procedure | Standards | Frequency |

1 | Burnishing should be done using a bassinet brush making sure not to run the machine for too long a period as the floor finish could be damaged. | The floor surface should have a pearl like lustre, but does not require a highly reflective shine and is free of dust, grit, litter, marks and spots. | |

2 | After the floor has been burnished, it must be swept with the sweep mop again. NB: Polisher should be used as per Equipment Operational Procedure and in a safe manner as shown during training. |

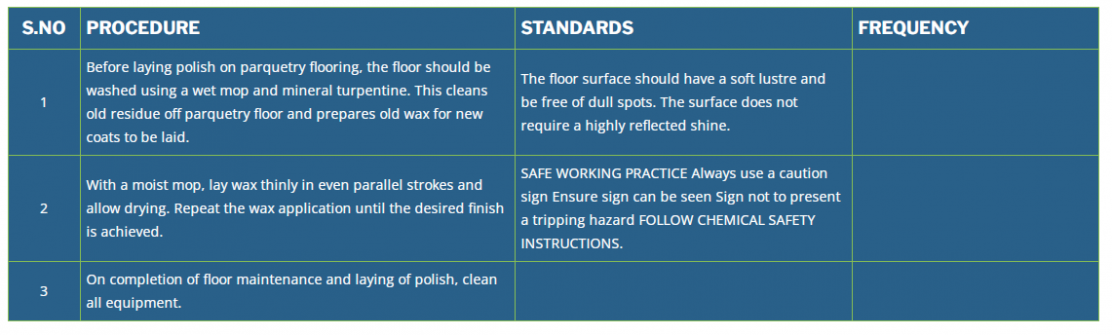

2.11 Parquetry Floors-Laying Wax

S.no | Procedure | Standards | Frequency |

1 | Before laying polish on parquetry flooring, the floor should be washed using a wet mop and mineral turpentine. This cleans old residue off parquetry floor and prepares old wax for new coats to be laid. | The floor surface should have a soft lustre and be free of dull spots. The surface does not require a highly reflected shine. | |

2 | With a moist mop, lay wax thinly in even parallel strokes and allow drying. Repeat the wax application until the desired finish is achieved. | SAFE WORKING PRACTICE Always use a caution sign Ensure sign can be seen Sign not to present a tripping hazard FOLLOW CHEMICAL SAFETY INSTRUCTIONS. | |

3 | On completion of floor maintenance and laying of polish, clean all equipment. |

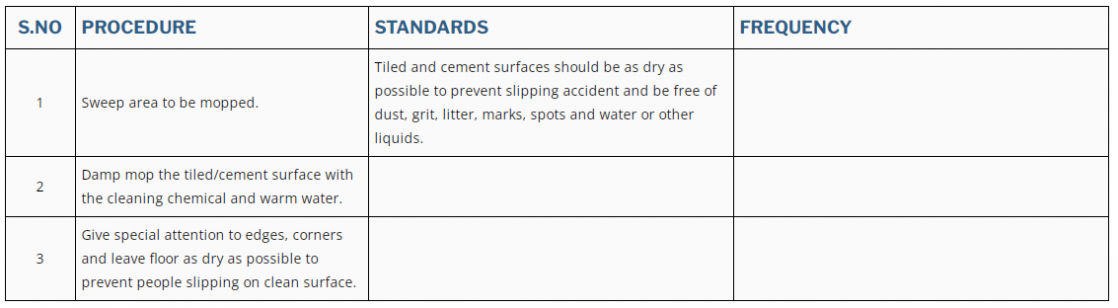

2.12 Floor Cleaning-Tiled or Painted Cement Surfaces

S.NO | Procedure | Standards | Frequency |

1 | Sweep area to be mopped. | Tiled and cement surfaces should be as dry as possible to prevent slipping accident and be free of dust, grit, litter, marks, spots and water or other liquids. | |

2 | Damp mop the tiled/cement surface with the cleaning chemical and warm water. | ||

3 | Give special attention to edges, corners and leave floor as dry as possible to prevent people slipping on clean surface. |